what is used to cut internal threads

In the realm of precision engineering, internal threading tools have emerged as pivotal components for countless applications. These specialized tools help manufacturers and machinists create accurate threaded holes in various materials like metal, plastic, and wood. The significance of these tools is underscored by their ability to enhance efficiency, reduce errors, and minimize production time—addressing common pain points faced by engineers. Modern businesses require these tools to improve threading quality which can lead to an increase in production output by as much as 25%. In environments where precise engineering is crucial, such tools can make all the difference in project success.

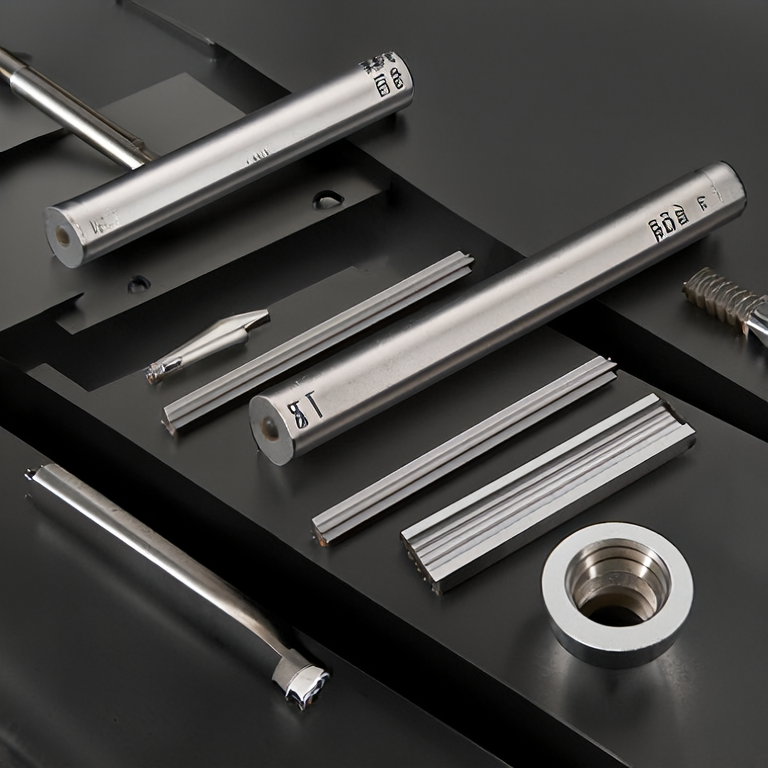

Definition of Internal Threading Tools

Internal threading tools are cutting tools designed specifically to create threads inside a cylindrical or conical hole. They come in various forms, such as taps, which are the most common types used for forming internal threads. When discussing this subject in industry terms, it\'s important to understand that these tools can either be hand-held or machine-operated. Taps can be further divided into hand taps, machine taps, and spiral taps, each serving distinct purposes depending on the material and complexity of the threading required.

Application Scenarios for Internal Threading Tools

Internal threading tools find applications in numerous industries:

- Automotive Manufacturing: These tools are used to create threaded holes for bolts and fixtures in engine components.

- Aerospace Engineering: Precision is paramount, and these tools help create internal threads in lightweight yet strong materials important for aerodynamics and safety.

- Construction: Creating fixtures and ensuring sturdy connections in structural components requires dependable internal threading tools.

- Electronics: Creating threaded sockets for components is essential in device assembly.

- Medical Devices: Internal threading tools are vital in producing safe and accurate fittings for medical equipment.

By streamlining the threading process, manufacturers in these fields can achieve higher accuracy and reduce the rate of defective products, addressing issues like rework and wasted materials.

Brief Description of Advantages

The importance of internal threading tools cannot be overstated. One key advantage is their ability to enhance efficiency: accurately engineered internal threads improve the fit between components, thereby increasing the overall performance of manufactured goods. Studies from industry sources indicate that accurate threading reduces assembly time by about 40%, allowing for quicker time-to-market without compromising quality. Furthermore, they offer cost savings; reducing the rate of thread failures translates to fewer returns and repairs—metrics that can enhance the bottom line of any production facility.

Next Steps for Further Understanding

To make the most out of internal threading tools, it is vital for users to familiarize themselves with the operation and maintenance of these tools. A key resource would be to consult the user guide provided by the manufacturer—especially those from trusted brands like GSR. Understanding the correct application and adjustment techniques can significantly influence longevity and performance.

FAQ about Internal Threading Tools

-

What materials can internal threading tools work with?

- Internal threading tools are versatile; they can be employed on metals, plastics, and even wood, depending on the type of tool used.

-

How do I choose the right internal threading tool for my project?

- Consider the material, thread size, and application requirements. Consult the technical specifications from the tool manufacturer for guidance.

-

What maintenance is needed for internal threading tools?

- Regular cleaning and proper storage are necessary to ensure longevity. It\'s also crucial to inspect tools for wear and replace them as needed.

-

Can anyone use internal threading tools?

- While simple hand taps can be used by anyone with basic mechanical skills, machine taps and more complex tools often require training and experience.

By understanding the intricacies of internal threading tools and their applications, engineers and manufacturers can make more informed choices that lead to improved precision and productivity in their projects. For those interested in deeper exploration, consultations with manufacturers like GSR can further clarify product specifications and best practices.