What Are Internal Thread Cutting and External Thread Cutting?

Threaded parts are a fundamental metalworking process and the global market now encompasses a wide range of connectors and fittings. As a result, determining the correct thread for your application is becoming increasingly challenging. It is important to explore the different threading techniques available, and GSR is here to share them with you.

What is a machined thread?

A thread refers to a continuous spiral ridge. A spiral ridge has a uniform cross section on different surfaces of a cylinder or cone. It can be formed on the surface of a nut (inside) or a screw/bolt (outside).

The main function of the thread is to act as a coupling between the two mechanisms. Due to the coupling, there is a transfer of motion. The movement can therefore help to gain a mechanical advantage.

Some technical terms

The following terms will help you to better understand machining threads.

Top of tooth: This is the surface of the thread on the side of the connection. The top of the thread is the area furthest from the cone or cylinder from which the thread protrudes. In other words, it is the top of the thread.

Tooth root: The tooth root is the threaded surface that connects the tooth side of the adjacent threaded tooth pattern. It is the area immediately adjacent to the cone or cylinder from which the thread protrudes. In other words, it is the bottom of the thread.

Pitch: This is the distance of the parallel area measured between the corresponding areas on the adjacent threads. The pitch circle diameter is the diameter of the theoretical cone or cylinder.

Helix angle: When you are using straight threads, the helix angle is the angle formed by the helix thread relative to the thread axis. On the other hand, the helix angle of a tapered thread is formed by the tapered helix area of the thread.

Types of threads cutting

There are different criteria when it comes to classifying threads. In this section, we will discuss internal and external threads.

Internal threads

Internal (female) machined threads are threads on concave surfaces. These types of threads are machined with a single lip threading tool. You need internal threads in order to insert the screw into the workpiece. The thread cutting process for internal threads can be done by hand tapping or by machine tapping.

How do I cut?

1. drilling core holes (twist drill)

2. Countersink (countersink)

3. cutting internal threads (hand tapping/machine tapping)

External threads

External threads are also known as male threads. Common external threads include screws, plug gauges, bolts or studs. For parts that are eligible for turning, external threads can be extended through the length of the part. For external threads, threading on a lathe is very effective. You can also cut them manually using a round die. Dies are usually available from a fixed stock of moulds. Manufacturers use round dies as the counterpart for internal threads.

Which tool to use?

1. Lubricant

2. round bar

3. Round die (external thread)

4.Tooling stock

5. Screwdrivers

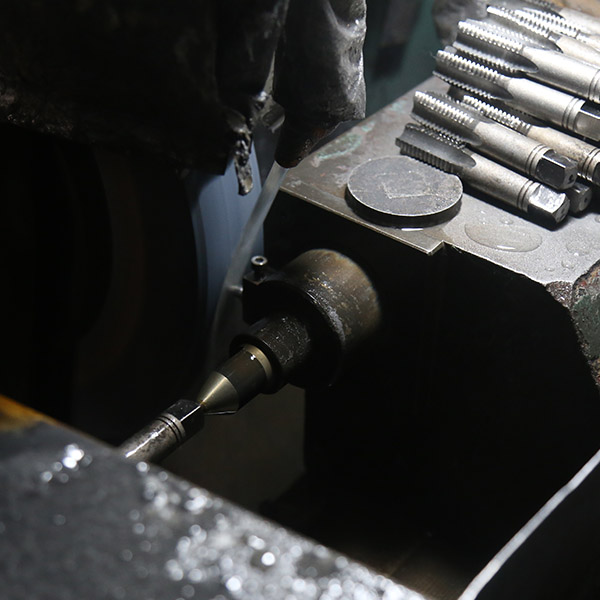

Factory Show:

Machined thread cutting is an important aspect of the manufacturing process. You should discuss this with a thread technology specialist. We are a German manufacturer with modern production technology and dynamic innovative power from the tool city of Remscheid with competence based on experience since 1889. Contact here, and we can offer you the best possible service.