High Quality Machine Tap Factory, Spiral Flute blind hole M8 M10x1.5 M12

1. Spiral Flute: The grooves on the tap cone are not straight, but spiral along the axis

2. The main purpose of this design is to optimise the direction of chip removal.

Advantages (focus on chip removal)

The design of the spiral flute tap offers several significant advantages, making it ideal for specific machining applications, particularly when tapping blind holes and machining tough materials.

1. Excellent chip removal performance

Upward chip removal (right-hand spiral flute): This is the most common type of spiral flute tap. The spiral flute forms a natural ‘conveyor channel.’ During the tapping process, the chips produced are pushed upward (towards the tap shank) along the spiral flute and discharged from the hole.

Effectively prevents chip accumulation and blockage at the bottom of holes (blind holes), significantly reducing the risk of tap jamming, blade breakage, or thread damage caused by chip blockage.

2. Higher processing quality

Smooth chip removal reduces scraping and squeezing of the machined thread surface, resulting in a smoother, more precise thread surface and better thread quality.

Reduced vibration caused by chip clogging, resulting in more stable machining

3. Lower cutting force

The spiral flute structure itself has a certain cutting rake angle, which makes cutting smoother.

Smooth chip removal reduces friction resistance between chips, workpieces, and tap flute walls.

Effect: Reduces the torque required for tapping, reducing the load on the machine tool spindle and workpiece. Particularly better for using in low-power equipment, and

workpieces with insufficient rigidity (such as thin-walled parts) or deep hole machining.

4. Longer tool life

The reduction in cutting force reduces wear on the cutting edge.

Reduced risk of sudden chipping and breakage caused by chip blockage

Effect: Significantly extended the tap life and reduced the cost per piece and the frequency of tool changes.

5. Higher machining efficiency

Machining at higher cutting speeds

Longer tool life reduces tool change time

6. More suitable for machining ductile materials

When machining materials such as stainless steel, low-carbon steel, aluminium alloy, and copper alloy that produce long chips, have good toughness, and the chips are

difficult to break. The forced chip removal capability of spiral flute is extremely advantageous in this scenario and is almost an essential choice.

7. More suitable for blind hole tapping (right-hand spiral flute)

The right-hand spiral flute pushes the chips upwards out of the hole, perfectly solving the problem of chips having nowhere to go at the bottom of blind holes. It is the main

choice for tapping blind holes.

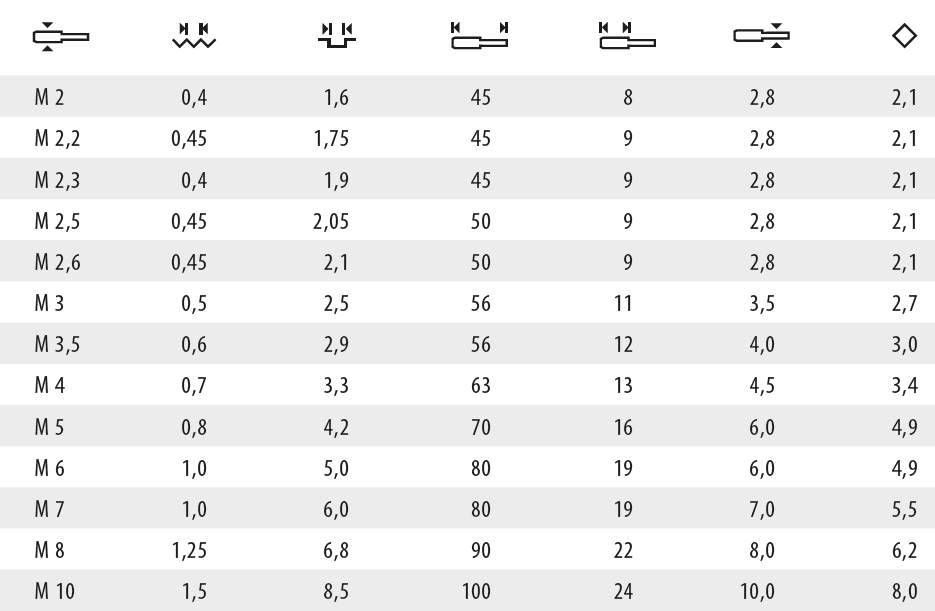

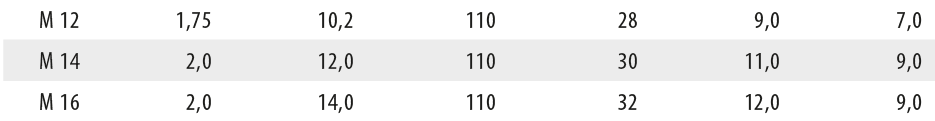

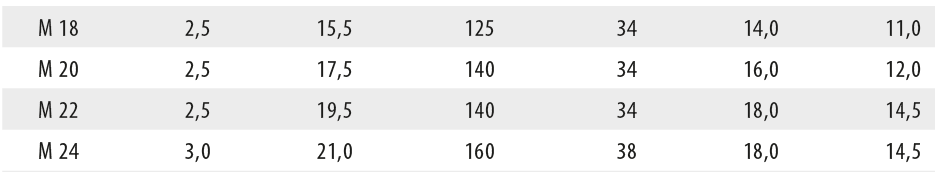

Technical Data:

| Standard | DIN371/376 |

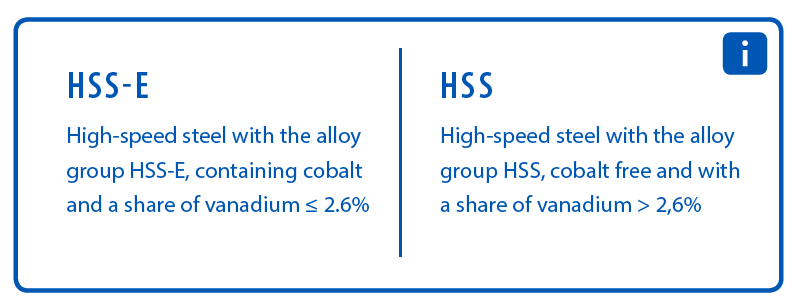

| Material | HSS-G/HSS-E |

| Tolerance | ISO2(6H) |

| HRC | 61-66 |

| Surface | Bright Finished/PVD Coating |

| Flute Type | Spiral Flute,35° |

| Cutting Direction | Right |

| Thread Angle | 60° |

| Square | DIN10 |

| Application | Internal thread cutting for blind hole |

Brief Introduction:

Machine taps for ISO metric coarse threads is suitable for cutting internal threads with a machine. The DIN 371 version has a reinforced shank (up to M10) and the DIN 376 version has a reduced shank.

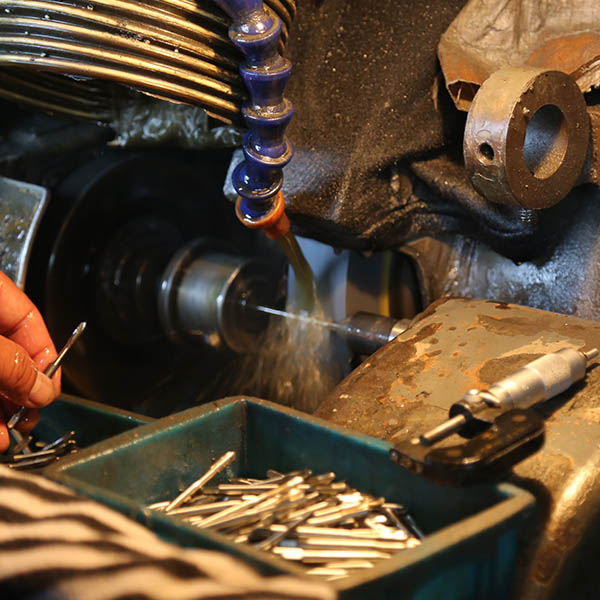

Factory Show: