What is a machine threading tap

Machine threading tap is a special tool for cutting threads on different workpieces. Machine threading taps are typically used in mass production or when a large number of threads need to be produced quickly. You can cut threads in one operation. Machine threading taps are usually made of HSS M2, HSSE or HSSE PM steel.

Advantages of machine threading taps

The use of machine threading taps offers a number of advantages over other thread cutting methods:

Speed: Machine threading taps allow for fast thread cutting, thus increasing productivity.

Repeatability: Machine threading taps allow high repeatability. By using a machine, threads can be cut again and again with the same precision, which is important when several identical threads are needed.

Versatility: Machine-threading taps are suitable for a wide variety of materials, making them an indispensable tool in many industries.

To get the most out of your machine's threading taps, follow these tips:

Material selection: Select the right machine tap for the material to be machined. Different materials require different cutting geometry and speeds.

Lubrication: be sure to use enough lubricant when cutting threads,. This reduces friction and extends the working life of the machine threading tap.

Cutting speed: Ensure the correct cutting speed. An incorrect cutting speed can result in unclean and disproportionate threads, and what's worse, it can even break the taps

Replacement: To replace the worn threading taps in order to have the best performance. Worn threading taps can result in unclean or damaged threads.

Conclusion

The machine threading tap is an indispensable tool for fast and accurate thread cutting. They offer many benefits, including speed, accuracy, repeatability, and versatility. By following a few tips, you can make the most of your machine threading tap and get the best results.

The Spiral Flute Machine Taps

Spiral fluted machine taps are the most popular taps applied in the manufacturing industry today. DIN371 and DIN376 HSSE Spiral fluted machine taps are one of GSR's premier products. Besides, we have also other standard like JIS and ISO529.

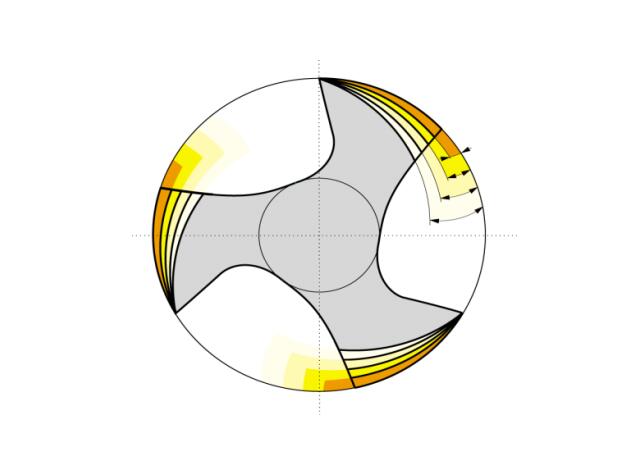

Spiral fluted machine taps have flutes that wrap around the tap’s axis in a spiral or a helical configuration. The tap is used mainly for tapping threads in blind holes. A spiral fluted tap pulls the chips out of the hole toward the tap shank and opposite of the tapping direction. Depending on different working conditions, different spiral angles are applied, the common ones from GSR being 15° and 40° right-handed. Generally speaking, the larger the helix angle, the better the chip removal performance.

The Chip groove

The whole spiral groove should be made as a cicular arc, the front edge surface arc radius should be large enough, the groove bottom arc radius should be selected in the right place, because the bottom arc radius is an important element to affect the cutting shape and chip removal, if arc radius is too large, it will increase the curvature of the chip to caused the chip removal difficulties, arc radius is too small, it will increase the additional deformation of the chip, so that the cutting force will be increased.

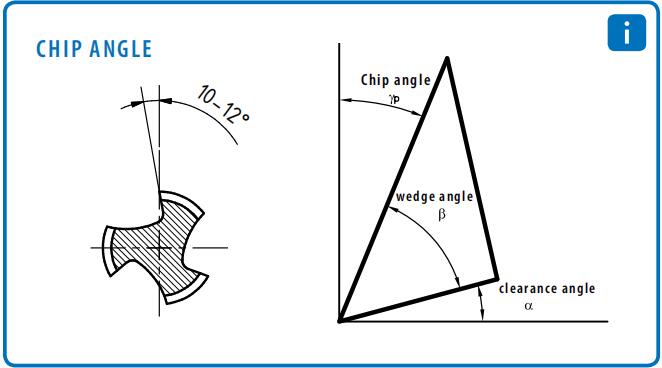

Chip angle

The front angle should be determined according to different workpiece materials, the actual working front angle of spiral flute taps will increase, the front angle is too large to affect the edge strength, so the front angle of spiral flute taps is generally taken as 4 ° ~ 8 °.

Back angle

In order to reduce the friction when cutting, the cutting tooth should be chamferred, shovel grinding amount of 0. 02 ~ 0. 03mm, at the same time, in order to increase the tap cutting strength and cutting stability, cutting back angle should be as small as possible, generally take 3 ° ~ 5 °.

Hangzhou GSR-Threads Tools Co.,Ltd is a professional manufacturer of spiral flute machine taps, regularly from size M2-M30, We have advanced manufacturing equipment, perfect quality control system, so that each tap to the hands of customers can play the best performance! For more details, please visit us at www.gsrthreads.com