To do the threads repairing jobs in a professional way

Thread repair kits - the right tool for efficient restoration of damaged threads

Threads are often subjected to high loads, tremendous forces and vibrations, etc. Therefore, thread damage is a common problem in the field of machining and maintenance, especially in equipment with high loads and frequent use. Damaged threads not only affect the normal use of the equipment, but can also lead to equipment failure and even affect safety. In order to repair damaged threads, thread repair kits have come into being.

This article will describe the definition of a thread repair kit, the tools included, the applications, and how to properly select a thread repair kit.

1. Definition

The Thread Repair Kit is a professional tool kit for repairing threads that are not functioning properly due to overuse, wear or damage. It helps technicians to restore thread integrity without replacing the original part by using a range of specialised tools.

2. Tools that make up a thread repair kit

- H.S.S. Drill

- STI Tap

- Installation tool

- Thread inserts (1.5D)

- Break Tool

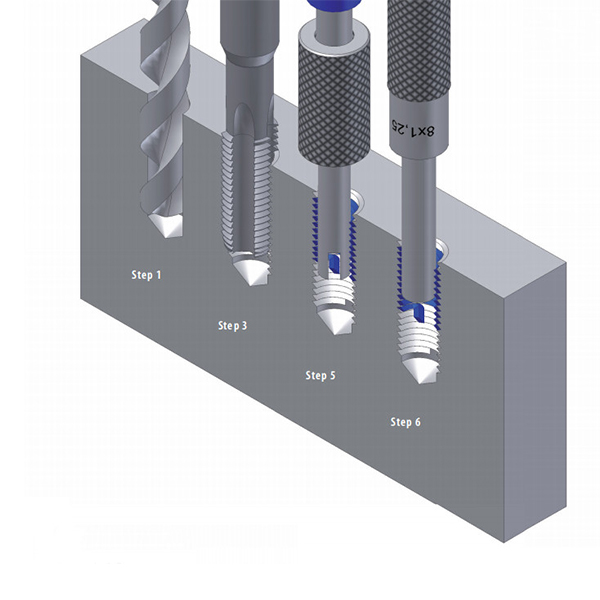

Correct Procedure

Drilling

Damaged threads are drilled out with a corresponding twist drill.

Threading

Use the screw tap to cut an new thread, while cutting oil is recommended

Installation of the threaded insert

Place the matching thread insert into the groove of the install handle.

Screwing in of the thread insert

Screw the insert in the thread direction.

Tang breaker

Take out the install tool and remove the tang with the tang break tool.

New thread

The new thread has the exact size of the original thread.

3. Benefits of using a thread repair kits

Cost Savings: Using a thread repair kit can result in significant cost savings compared to replacing an entire part or piece of equipment. After repairing the threads, the original part can continue to be used, avoiding costly re-purchases and replacements.

Increase equipment life: Thread repair kits can quickly restore the function of threads, avoiding equipment downtime due to damaged threads, thus extending equipment life.

Reduced maintenance time: The use of thread repair kits enables thread repair to be completed in a shorter period of time, reducing downtime and increasing productivity.

Simplified operation: Thread repair kits are usually supplied with detailed instructions for use, enabling even inexperienced technicians to perform thread repair in a simple manner.

Adaptable: Thread repair kits can be applied to a wide range of different materials and can handle a variety of different sizes of thread damage

Enhancement of thread strength: the use of steel wire thread inserts in some soft materials can significantly improve the strength and load capacity of the thread, and enhance the service life of the equipment.

4. Proper selection of a thread repair kit is critical to the effectiveness of the repair. Here are a few key factors to consider when making your selection

Thread type and specification: first confirm the type of thread to be repaired (metric or imperial) and the specification of the thread (e.g. pitch, thread diameter, etc.)

Type of material required for repair: The material of the thread damage also needs to be considered. Different thread repair kits may be suitable for different metals or alloys. Ensuring that the selected repair kit is compatible with the material of the damaged part will ensure the effectiveness of the repair and its reliability in the long term.

Thread strength after repair: For general strength threads, only ordinary wire thread inserts are needed; however, for threads that need to withstand high strength, reinforced repair tools such as key locking threaded inserts may be needed. Choose the right tool for the specific situation.

Brand and quality: There are many brands and types of thread repair kits on the market. By choosing a reputable brand and reliable tool set, you can avoid failed repairs or further damage due to the quality of the tool.

Number of tools and accessories: Some thread repair kits contain a wide range of accessories, such as screw taps of different sizes, twist drills, thread inserts, etc. The diversity of these tools can meet different repair needs. Choosing the right kit with the right tools according to the actual needs can improve the efficiency and quality of the repair.

5. Concluding remarks

The Thread Repair Kit provides an efficient and cost-effective solution for industrial repair and equipment maintenance. It not only restores the function of damaged threads and avoids

equipment downtime, but also saves costs and improves productivity. When selecting a thread repair kit, users need to choose the right tool set based on the type, size and material

properties of the thread. Choosing the right thread repair tool not only improves the repair quality, but also extends the service life of the equipment. For companies that need to perform

thread repair, investing in a high-quality thread repair kit is definitely a worthwhile choice!

GSR team have dedicated ourselves to the topics of defective threads repairing for more than 15 years. That's why we know exactly how you can repair damaged threads and contribute

to a long service life and increased load capacity. At GSR, you will find thread repair kits for different sizes and types, every question can be answered by professional technicians. Our tools

are made from the highest quality raw material (HSS-M2 or HSSE) and with great precision, for fantastic results. When you need to easily repair and strengthen your threads, our thread repair set

is your piror choice.