Carbide Drills and HSS Drills

Carbide Drill Bits vs High Speed Steel Drill Bits, do you understand?

Drilling is a crucial process in any industrial project. Using the right tool is very important as using the wrong tool can lead to bad results, wasting time and money.

Holemaking is the process of drilling holes in a workpiece using a drill. Tool substrate may not sound like an important factor, but it can significantly affect the drilling process in a variety of ways, including cost, machine performance, setup, and material.

What is a High Speed Steel drill bit?

High speed steel drills are one of the oldest drills used in metalworking. These bits are made from carbon steel, tungsten and other materials that make them affordable for many applications.

HSS drills can be used for many materials including steel, stainless steel, cast iron, etc.

Why use HSS drills?

HSS drills are typically used on manual machines. This is a great application if you are looking to reduce your tooling costs. HSS has good heat resistance and is suitable for drilling a wide range of materials.

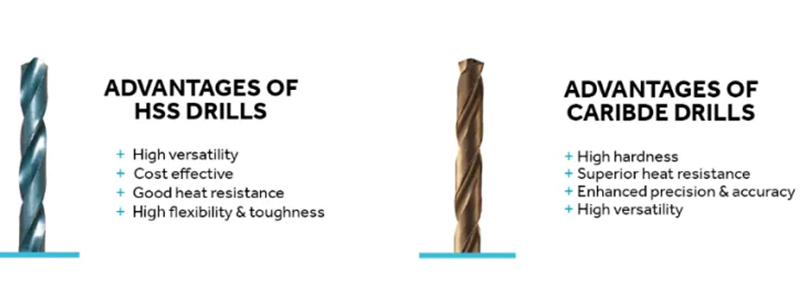

What are the advantages of HSS drills?

1. Versatility: HSS drills can handle a wide variety of materials, including wood, plastic, aluminum, mild steel, cast iron and stainless steel. This versatility makes them a reliable choice for holemaking applications in many industries.

2. Cost-effective: HSS drills are more economical than carbide drills, making them a cost-effective and efficient solution for general-purpose holemaking operations. Their impressive tool life and resharpenability further add to their economic value.

3. Heat Resistance:HSS drills have excellent heat resistance and maintain their cutting performance even at high speeds. They have the ability to dissipate heat efficiently, which helps prevent tool overheating and extends tool life.

4. Flexibility and toughness: HSS drills are tougher and their construction is more robust than carbide drills. HSS bits are also flexible, making them less likely to break or splinter, especially if they encounter unexpected obstacles while drilling.

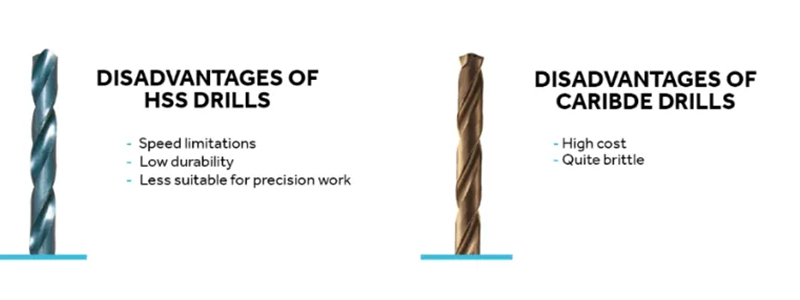

What are the disadvantages of HSS drills?

1. Speed Limitations: A major disadvantage of HSS drills is that they cannot achieve the same cutting speeds as carbide drills when drilling through harder materials such as hardened or heterogeneous steels. In some applications, slower drilling speeds result in reduced efficiency and shorter tool life.

2. Durability: Although HSS drills are very durable for their price range, they are not as durable as carbide drills. They tend to wear out faster, especially when drilling through abrasive materials or performing heavy-duty cutting tasks. They may need to be replaced or resharpened frequently for extended use.

3. Less suitable for finishing: HSS drills are less suitable for precision drilling operations because of the relatively large drilling point of HSS drills compared to carbide drills. When drilling small or complex holes where precision is essential, carbide drills are preferred.

What is a carbide drill bit?

Carbide drill bits are a type of drill bit made of tungsten carbide, which is a very hard and durable material. Carbide drills are typically used for drilling hard materials such as steel, stainless steel, and cast iron.

What are the advantages of carbide drill bits?

1. Hardness: Carbide drills are known for their exceptional hardness compared to HSS drills. They are made of tungsten carbide and cobalt and can effortlessly drill through hard materials such as stainless steel, hardened steel, cast iron, and even bore through abrasive materials such as fiberglass. This enhanced hardness leads to higher productivity and durability.

2. Excellent heat resistance: Unlike HSS drills, which lose their cutting edge when exposed to high temperatures, carbide drills maintain their performance even at extreme temperatures. This makes them ideal for high-speed drilling operations or long drilling sessions where a lot of heat is generated.

3. Precision and accuracy: Carbide drills offer superior performance in precision drilling. Their powerful and sharp cutting edges produce cleaner, more accurate holes, reducing the chance of inaccurate or irregularly shaped holes.

4. Versatility: Carbide drills have remarkable versatility and can effortlessly drill through a variety of hard and soft material types. This can include stainless steel, hardened steel, exotic, aluminum and more. Carbide drills are designed to handle different drilling applications, and this versatility saves the hassle of switching between different drills and improves overall efficiency.

What are the disadvantages of carbide drill bits?

1. High cost: One of the main disadvantages of carbide drills is their higher cost compared to HSS drills. The production process and rare materials results in their higher price. However, considering their durability and superior performance, carbide drills prove to be worth the long-term investment.

2. Fragility: Although carbide drill bits are very hard, they tend to become brittle under certain circumstances. Excessive pressure, improper use, or accidental dislodgement can cause bits to shatter. Careful use of carbide bits and proper drilling techniques can prevent such problems.

In conclusion, HSS and carbide drills each have their own unique benefits. If you are looking for an affordable, versatile drill bit that can also handle a range of projects, then it is recommended that you use HSS drill bits.

However, if you're working with hard materials or need to keep the drill bit sharp for a longer period of time, a carbide drill bit may be a better choice.