Adjustable Tap Wrench Factory M1-10 M5-12

The GSR patented tool holders have been completely redesigned. Their new design is modern and unique. While designing these, however, optimising the function of the tools was the main focus. Main goal of the redesign was to increase the resilience of the tool body. Objective criterion for that was the maximum torque. And our goal was achieved: compared to the old models, the new tool holders have a demonstrable performance increase of 20% up to 40%.

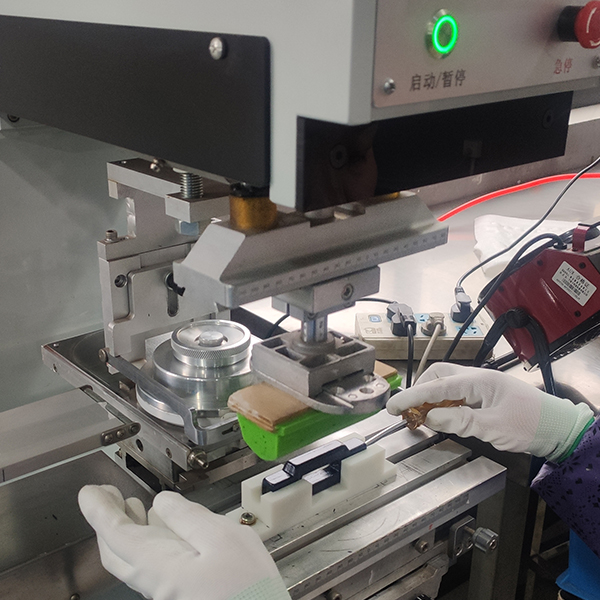

Another improvement are the environmentally sound manufacturing processes. Especially for surface treatment, efficient and environmentally friendly coating processes were developed and implemented.

Furthermore, we designed guides for internal and external threads which simplify the entire cutting process.

GSR TAP WRENCH

MADE OF DIE-CAST ZINC

These brand new GSR tap wrenches were completely redesigned. This ensures a higher resilience of the tool body. The hardened, adjustable clamping jaw can be adjusted via a guide groove milled into the chuck between the jaw and the handle. As a result, the jaw can be adjusted precisely and the tap clamped perfectly. The body is made of high-quality die-cast zinc and coated with an environmentally friendly powder coating, which is applied using a state-of-the-art closed-circulation coating system.

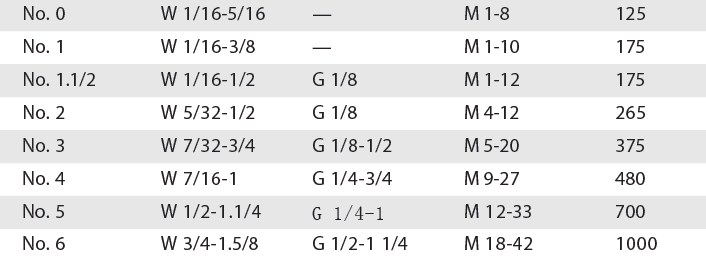

Technical Data:

| Standard | DIN1814 |

| Material | Zinc |

| Surface | Powder Coating |

| Body Color | Customized |

| Jaws | C45 Hardened |

| Handle | C45 Black Finished |

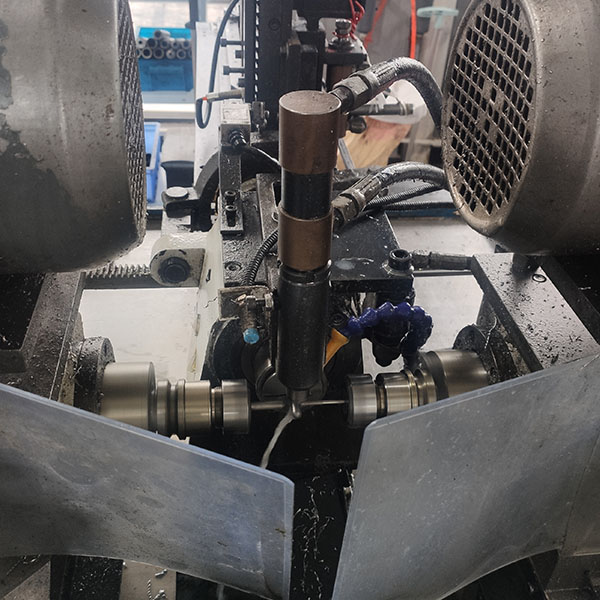

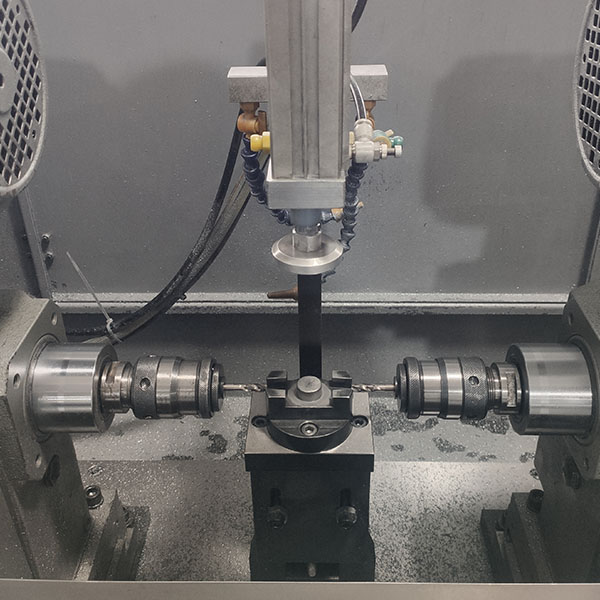

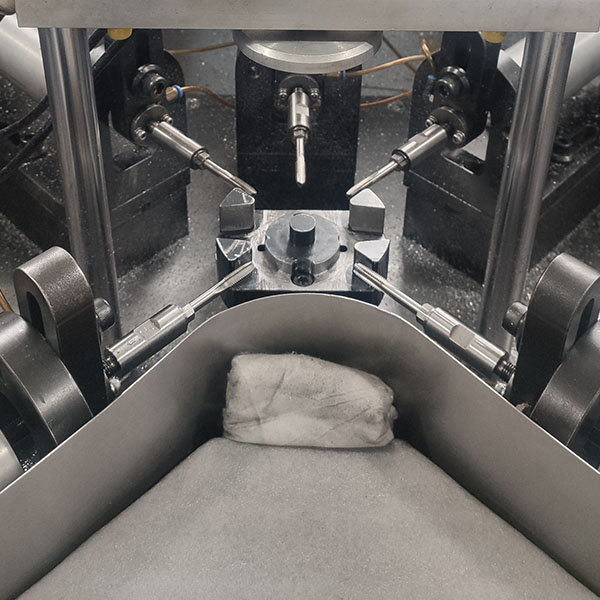

Factory Show: