A hole saw is a cylindrical cutting tool used to create holes in various materials. It consists of a circular saw blade attached to a drill bit. The blade typically has sharp teeth around its perimeter, designed to cut through the material when rotated. Hole saws come in various sizes and are often used with a drill press or handheld drill.

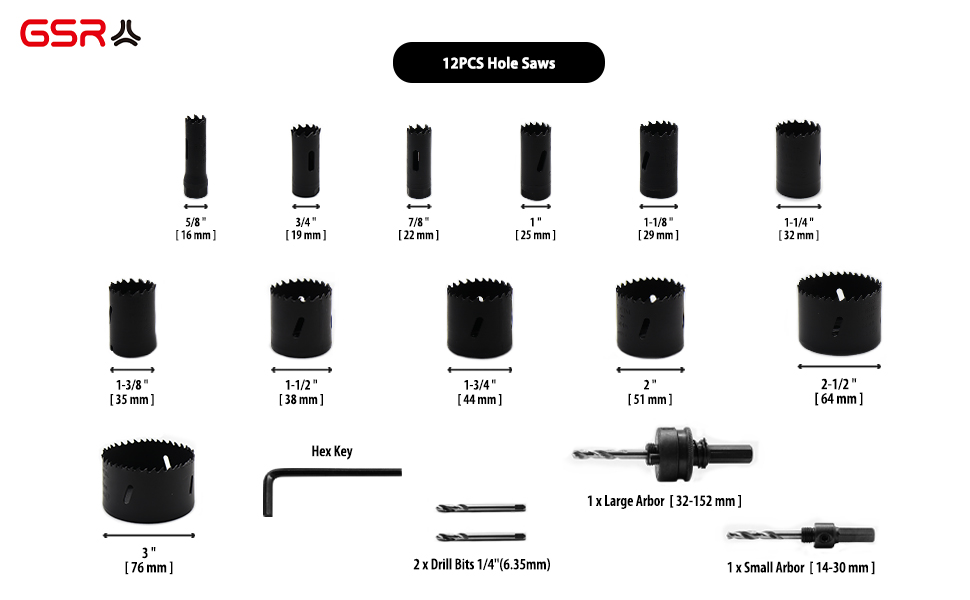

General Purpose Sizes: Includes 16mm (5/8''), 19mm(3/4''), 22mm (7/8''), 25mm(1''), 29mm (1-1/8''), 32mm(1-1/4''), 35mm (1-3/8''), 38mm(1-1/2''), 44mm (1-3/4''), 19mm(3/4''), 51mm (2''), 19mm(3/4''), 64mm (2-1/2''), 76mm(3''),

plus 2 pilot drill bits for replacement, 1 big arbor ( contain 1 drill bit), 1 small arbor ( contain 1 drill bit), 1 hex key

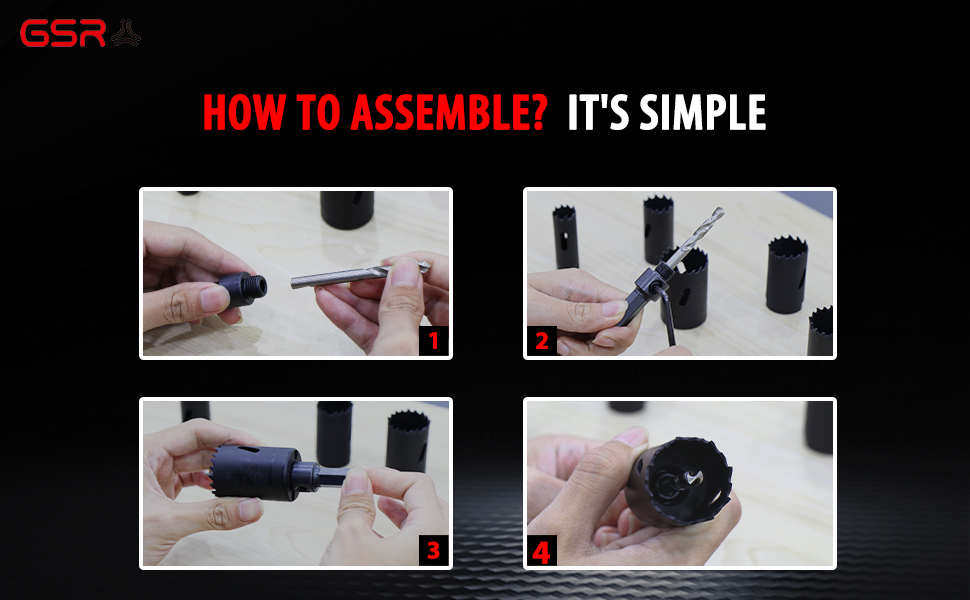

Follow below tips:

Insert the arbor via the back of the hole saw

Screw the hole saw into the arbors thread until it is tightened

Insert the arbor into the drill chuck and tighten it until you get a secure hold

Line your hole saw up on where you want to cut

Start by drilling slowly and gradually increase the speed of the drill

Occasionally back the hole saw out of the hole to clear dust

Once you have successfully drilled your required hole, remove the waste material from your hole saw

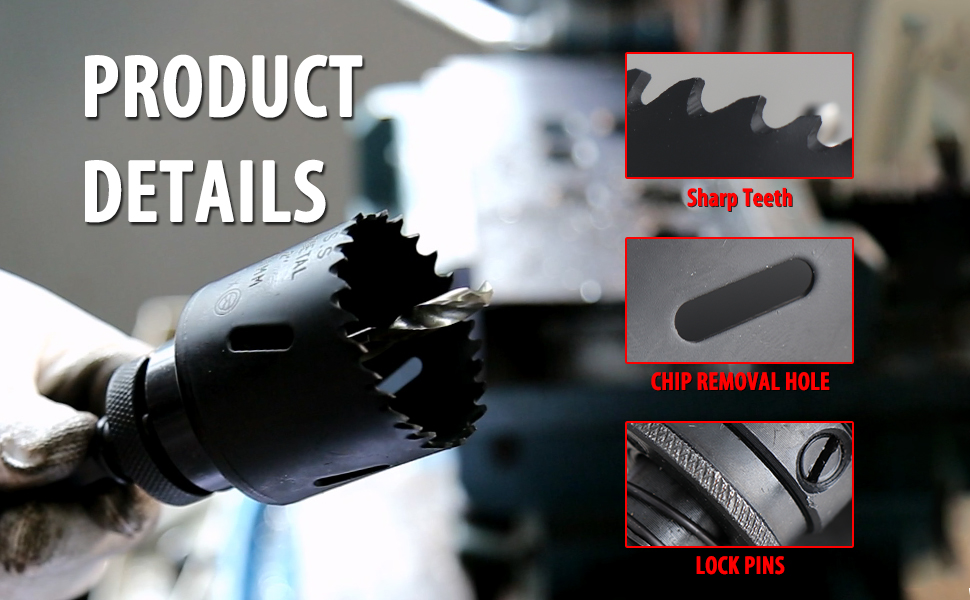

This type of toothing has alternate 4-6 different sized teeth per inch (TPI – teeth per inch). Hole saws will come with differing TPI's (teeth per inch). The higher the TPI, the slower the cut but smoother the finish. The lower the TPI, the faster the cut but it will be less smooth. Variable pitch is when the distance between the teeth varies. This provides a smoother cut with reduced wear on the blade

each hole saw contains slots on its sides. Their purpose is to allow chips and dust to escape

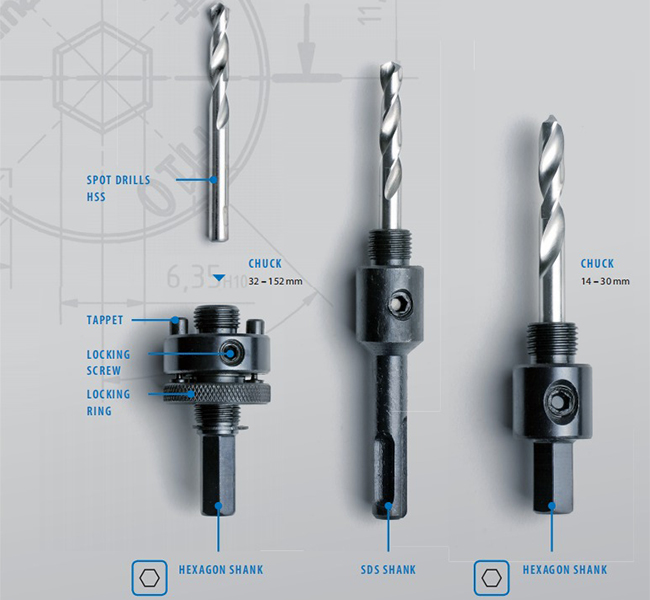

Details of the arbors, the small one is for how saw 14-30mm, and the big one is for hole saw 32-152mm

With our hole saw kit, you can easily cut through a wide range of materials, such as plastic plate, wood-based items, plywood, drywall, soft plaster, density boards, and even metal sheets. It is perfect for both DIY enthusiasts and professionals.

In GSR, we usually have two materials for how saw, one is HSS-M3, and the other is HSSE-M42 (8% cobalt)

M3 material usually refers to M3 high-speed steel, which is an American molybdenum high-speed tool steel.

The main characteristics of M3 HSS are fine, evenly distributed carbide particles and good toughness. The specific chemical composition of M3 HSS includes carbon, tungsten, molybdenum, chromium and vanadium, and these elements make M3 excellent in terms of hardness and wear resistance. The hardness of M3 HSS can reach 60~66HRC, which is suitable for manufacturing various types of general tools, such as turning tools, planer tools, taps, drills, etc.

The hole saws made by HSS 8% cobalt can also be used on stainless steels such as V2A and V4A sheets. More durability and longevity

The cutting depth depends on the depth of its cup-like shape. Most hole saws have a fairly short aspect ratio of diameter to depth, and they are used to cut through relatively thin workpieces. Common hole saw depths we have are 38mm

In GSR, the holes saws for use with portable drills are commonly available in diameters from 14 to 210 mm, or in the US, 9/16 to 8-17/64 inches.

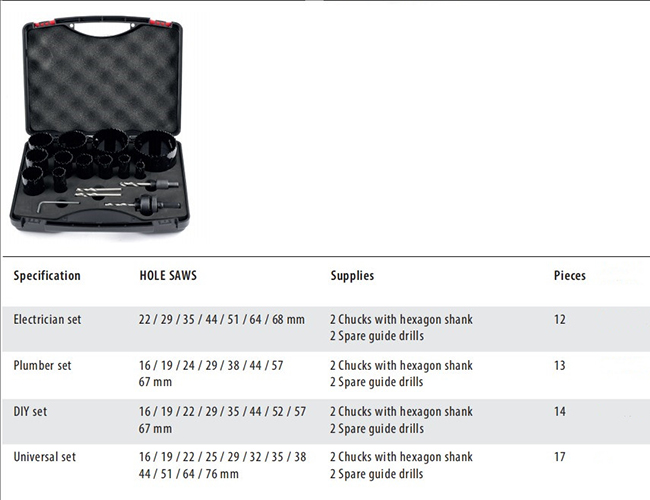

There are other sets available

Electrician Set - 12pcs 22/29/35/44/51/64/68.

Plumber Set - 13pcs 16/19/24/29/38/44/57/67mm

DIY Set - 14pcs 16/19/24/29/35/44/52/57/67mm

Package Dimension: 28x23x8cm